From different angles, you can divide soap into many types.

From use, it can be divided into toilet soap, non-toilet soap (used for cleaning heavy dirt), laundry soap, and medical soap.

Morphologically, there are bar soap and liquid soap.

From composition, there is goat milk soap, vegetable oil soap, and even luxury soap made of high-quality raw materials.

Here we focus on the different manufacturing processes of soap, they are triple-milled soap(Milled), melt&pour soap(M&P), and cold-process soap(CP).

| Difference/ Process | Milled | Melt&pour | Cold-process |

| Material | soap-base | soap-base | fatty acid+ NaOH |

| Sodium aliphatate | 60% | 20% | 50% |

| Process | milled by machine | melt→ molding | saponify→ molding |

| Lead time | 1 hour | 12 hour | 3 month |

| pH value | 8.5-9.8 | 9-10.5 | 8.5-10.5 |

| Cleaning | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ |

| Moisturizing | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| Hardness | hard | moderate | harder and harder |

| Appearance | simple, rustic | smooth, distinctive | realistic, gorgeous |

| Cost | low | medium | high |

| Pros | durable | more customizable | more natural |

| Cons | high MOQ | short-life | long lead time |

Material

The main component of all soaps is sodium aliphatate, which is the reaction of fatty acid+sodium hydroxide. This process is called saponification, and the semi-finished product is called soap-base. As the division of labor in modern industry is becoming more and more detailed, there are factories that only produce soap-base, and soap manufacturers only need to purchase that for secondary processing and creation. learn more about the ingredients in soap.

Milled and M&P soap is produced with ready soap base, but CP soap must start from saponification.

Sodium aliphatate

Even the soap base has different kinds. The same thing is that they contain various fatty acids sodium, but they are at different levels, causing the different viscosities to adapt to the different production processes.

Milled soap needs a thicker soap base. During the saponification process, glycerol and propylene glycol are not added for dilution, so the content of sodium aliphatate is higher, which can reach 60%.

M&P soap requires a thinner soap base so that it can be poured smoothly into the mold, so propylene glycol, sorbitol, and glycerin will be added during the saponification, so the sodium aliphatate content is smaller(they are diluted), less than 20%.

CP soap is a completely natural reaction process, and no intervention is made during saponification. The viscosity is a little thicker than M&P soap, but thinner than milled soap. The content of sodium aliphatate is also moderate. But the longer it is placed, the higher its content will be, because it is saponifying slowly.

Process

Milled soap is made and formed once by the machine completely, it can be used immediately after de-molding. Learn more.

M&P and CP soap are completely made by hand to create a unique shape and outstanding appearance. learn more

Lead time

Under normal temperatures, the saponification reaction is very long, so it generally takes 3 months for CP soap until the reaction is almost complete. The other two can be used after de-molding because they do not need the saponification process.

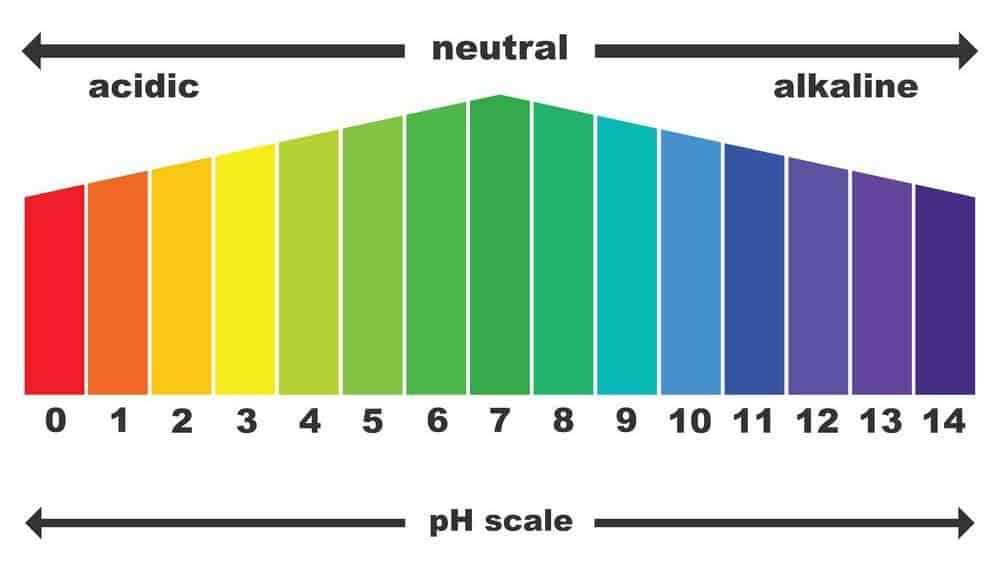

pH value

pH value is related to the degree of saponification. The more complete the saponification, the higher the pH value, which means the higher the content of sodium aliphatate, while the content of fatty acid is lower. In addition, the pH value of different sodium aliphatate is also different, the alkalinity of sodium stearate is the strongest. learn more

The pH of all the soaps is about 9, and due to the different manufacturing processes of different factories, it can be different. By the way, the pH value of soap can not reflect its cleaning ability. A neutral pH value should not be the direct standard for determining whether soap irritates the skin.

Cleaning

The cleaning is related to the content of different sodium aliphatate, since they are in different cleaning abilities. For example, sodium stearate has the strongest cleaning, the more it is added, the stronger the cleaning of soap is. Milled soap is believed to be more irritating because it contains more sodium stearate.

Moisturizing

Moisturizing is related to additives, such as glycerin, sorbitol, and various other superfatting agents.

Due to the difference in soap base, M&P and CP soaps have better moisturizing. Of course, milled soap can also be added with additives to achieve better moisturizing.

Hardness

The hardness is related to the sodium aliphatate it contains. they can be soft or hard, sodium stearate and sodium palmitate are hard oil, and the rest are soft. If a soap has more sodium stearate, it will be harder.

Milled soap must have the highest hardness, otherwise, the machine cannot mill and formed. M&P soap is the softest because a large amount of diluent (glycerin, propylene glycol, etc.) is added. CP soap will continue to saponify to produce stearic acid and become harder and harder even after forming.

Appearance

Due to the difference in thickness and process, all soaps will present different appearances.

A swirl or layered soap, such as marble, sunset, rainbow, etc., then it must be CP or M&P.

CP soap cools and hardens more slowly than M&P, it creates more realistic swirls and patterns. However, it cannot create a transparent effect, because sugar+glycerin cannot completely react at room temperature.

The milled soap is formed by the machine at one time, which can only produce the original appearance of the mold. With the thick texture, layering and swirls are more difficult.

Cost

Considering hand-made and production efficiency, milled soap is the cheapest, while CP soap is the most expensive.

Pros&Cons

Each type of soap has its pros and cons, and it has its own audience based on personal preferences or business needs.

Milled soap is easy to keep and durable because it is triple-milled by the machine. However, it requires a higher MOQ.

M&P soap has been recognized by more and more people for its excellent performance in aesthetics and production lead time, but its shelf-life and durability are a little poor.

CP soap is sought after because of more natural, but its three-month production lead time and high price are intolerable to the commercial. But for soap lovers, it’s perfect.