In the field of cosmetics, the printing of paper products is more targeted at retail boxes and labels. There are many types of printing and post-press, different methods, different operations, and different costs and effects.

Printing process

Lithography

The graphic part and the nongraphic part of the printing plate are on the same horizon, and the graphic part is covered with an oil film rich in grease, while the nongraphic part absorbs appropriate water. When the ink is applied, the graphic part repels the water and absorbs the ink, while the nongraphic part absorbs the water and forms the anti-ink area.

The ink is first transferred from the printing plate to the blanket, instead of directly printing on the paper. This is because the printing plate is made of aluminum (zinc or other materials) and with a hard surface, if it touches rough materials(such as paper) for a long time, it will be worn quickly. Therefore, the pictures and texts are transferred to the rubber roller first in an indirect way, and the rubber roller is lined with rubber cloth with canvas as the bottom. This is what we call “offset printing”.

Offset lithography is simple in plate making, low in cost, soft in color tone, rich and delicate in presentation. But due to the influence of water and ink, the color power is weakened and not such bright. Most of the paper packaging in cosmetics is printed in this way.

Intaglio

Intaglio printing relies on the concave mesh (used to store thinner ink) as the graphic part, at first, the printing plate cylinder is inked for the whole face, and then the doctor blade scrapes off the ink on the nongraphic part, leaving the ink on concave as the graphic part. The cylinder press on the back of the paper, so that the ink on the concave is directly transferred to the paper. The deeper the concave is, the more ink will be stored, then the deeper the printed image will be.

The intaglio printing machine is similar to the offset, there are also several groups of printing units, but they are more than offset, it can be 8 groups, and most of them are spot colors. When printing multi-color, it can be overprinted or indirect partial inking. It can be fed continuously on a single sheet or on a reel. It can be fed continuously on a single sheet or on a reel.

Intaglio printings with bulging lines, and rich layers, can express a strong color. The printing quality is the best of all. And its printing plate is durable, which is very suitable for large quantity printing. In addition, because the printing plate is not easy to be imitated and forged, it has the characteristics of anti-counterfeiting, the banknote is printed in this way. However, the production of printing plates takes a long time and the process is complex, so the cost of intaglio printing is very high. Therefore, it is less used in cosmetic packaging printing.

Relief

In contrast to intaglio printing, the graphic part of relief printing is prominent, and the ink can only be transferred to the graphic part but not the nongraphic part of the plate. Under the pressure of the plate cylinder, the ink is transferred to the paper, it’s similar to stamping. Flexography is a typical relief printing. It was originally used for corrugated paper. Because the surface of corrugated paper is very uneven, the printing plate must keep in touch with the cardboard, and flexography has enough flexibility.

The flexography machine is basically the same as the intaglio, it also has several printing groups and also has a doctor blade, but this doctor blade is used to ensure that the ink volume evenly applies to the plate, rather than scraping off the ink of the nongraphic part.

The relief print has a clear outline, powerful strokes, and bright colors. However, plate making is also difficult, and easy to be worn. It is also difficult to apply even ink when printing.

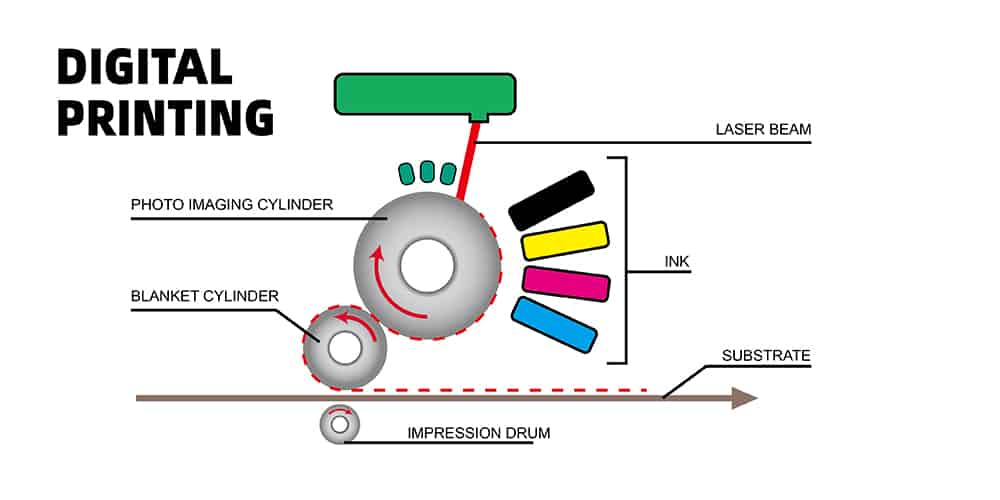

Digital print

Digital printing is copying digital images onto paper, the simplest ones, such as ink-jet printing and laser printing, are commonly used in office. Just a printer can complete the work, so no printing plate is needed. It is a cost-effective printing method, which is often used for proofing and a perfect small number of printing methods. There will be color differences from traditional printing, and it can not replace traditional printing at present.

| Printing | Litho | Intaglio | Relief | Digital |

| spot color | √ | √ | ||

| CMYK | √ | |||

| High solution | √ | √ | √ | |

| Small budget | √ | √ | ||

| <100pcs | √ | |||

| <1000pcs | √ | |||

| ≥1000pcs | √ | √ | √ |

Post-press

Lamination

Use adhesive, then over the plastic film on the surface, after heating and pressurizing, finally the paper and film bond together.

There is glossy and matte lamination, the glossy finish is bright while the matt finish is elegant. In addition to making the product more beautiful, this method can also be waterproof, tear-resistant, and fade-resistant.

Varnishes

Apply a layer of varnish on the surface, after leveling, drying, calendering, and curing, you can get a thin and uniform transparent and bright layer.

There are also gloss varnish and matte varnish, they can not only enhance the bright luster, but also play a role in waterproofing and oilproof, protecting the printed images and texts, and do not affect the recycling of paper.

Compared with lamination, this method is more environmentally friendly because there is no plastic.

Foiling

Foiling is to use heat transfer to print the metallics layer to the surface to form a special metal effect.

The foil is clear, colorful, shiny, and luxurious, which is one of the easiest ways to highlight important details.

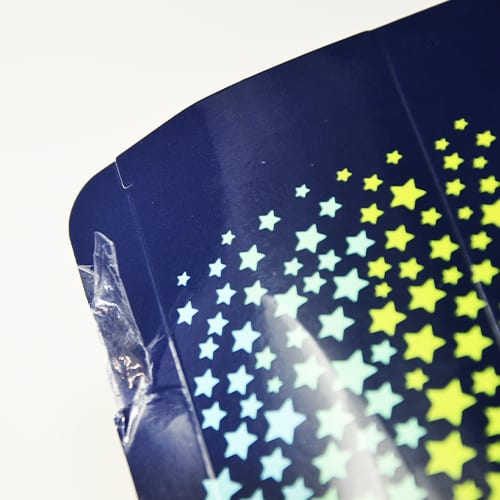

Spot UV

UV is a tough and transparent coating, applied as a liquid, and then becomes hard after exposure to ultraviolet light, resulting in a three-dimensional sense, showing a special artistic effect on your prints.

There are glossy, matte, even frosting, glitter, and colorful. It can be processed by screen print, flexographic, and intaglio.

Embossing&Debossing

Concave-convex embossing is a special way to decorate the printings. It uses a concave-convex mold to make deformation of printings under a certain pressure. This is a purely physical way.

Embossed figures show different depths, which have a distinct sense of relief, increasing the stereoscopic sense and artistic appeal of the printings.

Above are the most widely used post-press in cosmetics paper packaging. Of course, there are many kinds, such as fragrance ink, glow-in-the-dark, and thermography, and you can combine multiple finishes together, such as foiling in the debossing.

Prepress design

Offset printing is rich and delicate; Relief printing with a clear outline, powerful strokes, and bright color; Gravure printing has clear lines, fine and beautiful; Flexo printing has concise color blocks, with a strong visual impact. Different printing methods have their own specific requirements, which must be considered in the prepress design.

- For the offset printing product design, the main attention can be paid to these points: whether the resolution of the picture is enough; Whether the trapping value is suitable; For small text, try to avoid four color overlapping, so as not to increase printing difficulty; Whether the regular line and cutting line is complete; Try to avoid making the large and full field color blocks.

- Intaglio printing products shall be designed to avoid multicolor overprint. Because most of the materials used for gravure printing have more significant thermal shrinkage, and thermal deformation occurs during high-speed printing, it is more challenging to overprint.

- When designing flexographic prints, the following aspects should be avoided: avoid designing too small characters and too thin lines; Avoid the overprint of two-color or multi-color lines and characters; Avoid designing small inverted words and lines.

Problems in printings

- Color difference: the reasons may be poor quality of the original, inaccurate plate making, poor ink control, etc. learn more

- Dim color: the reasons may be poor original, poor plate-making, insufficient printing pressure, old printing machine, poor quality paper, low whiteness, etc.

- Scumming: The blank part is inked due to poor wetting of the printing plate.

- Smearing: the printing speed is too fast, and the ink has not solidified in time, causing the ink to transfer to other papers.

- Deinking: the imbalance of ink and wash during printing, which causes some ink on the ink roller to be replaced by water instead of sticking to the ink.

- Out of register: The error of printing trace overlap in the process of overprint printing.