Making boxes is a very creative thing, there are so many shapes and styles to choose from. But if you are not familiar with this, you may feel a bit confused and complicated. How do you know what kind of boxes your products need? In this article, we will explain the styles of folding boxes used most in the cosmetics industry and their adaptability.

Tuck-end box

A box with two openings, one at the top and one at the bottom of the box. Most of the openings are opposite or can be opened on the same side. It is convenient for packaging and has a wide range of uses, suitable for lighter goods, applicable to all industries, and has the advantages of low production difficulty and low cost.

Auto-lock bottom box

The upper part is tuck-end, and the bottom is auto-lock. Compared with the tuck-end box, it is better for bearing weight, and more suitable for heavier goods(such as candles). At the same time, because the bottom can be locked automatically when forming, the packaging efficiency can be improved.

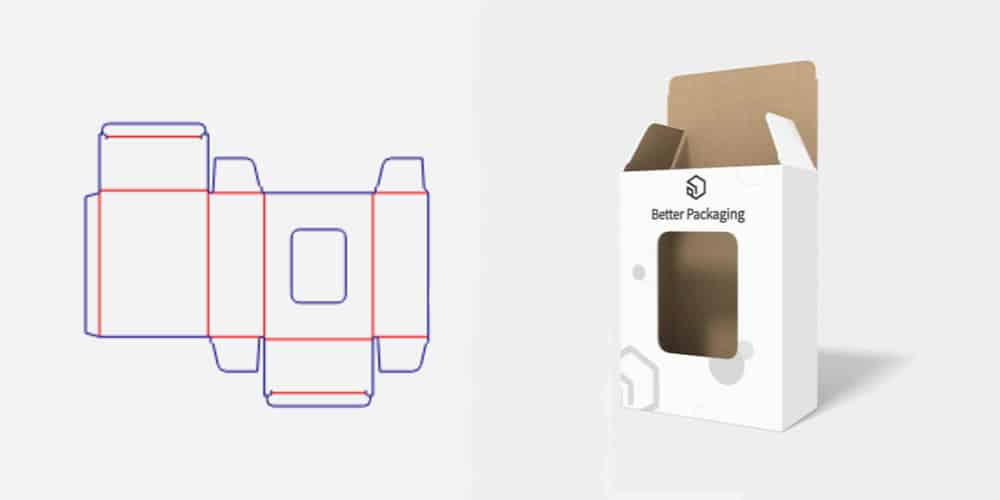

Window box

Cut holes in the box to open the window, or paste transparent patches to facilitate the perspective of goods. Let the products be displayed in front of us intuitively to facilitate customers’ observation and increase the credibility of the products. The advantage of window boxes is that you can see the internal products at a glance. No matter what type of box, windows can be opened in many ways, mostly used in bath gift sets.

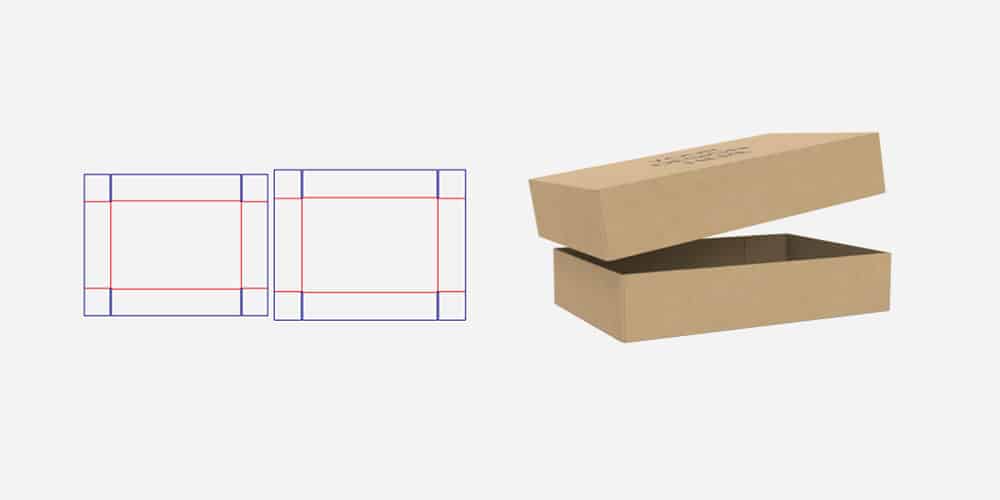

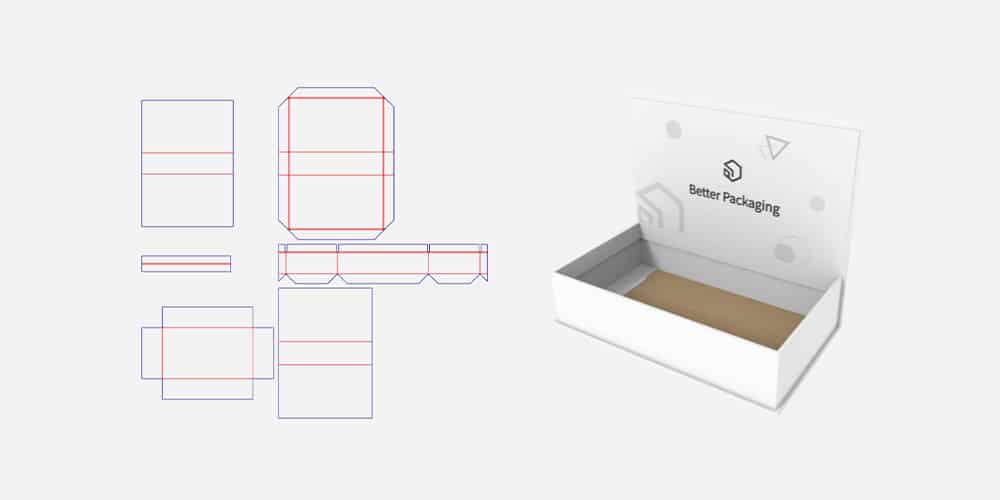

Lid and tray box

Also named the Two-Piece Boxes, the lid and tray are separated. Generally, used stiff cards and consume more material, most of them are formed by hand, so the cost is slightly higher, but the texture is good. An elegant packaging solution, very suitable for high-quality gift boxes and can improve the product image.

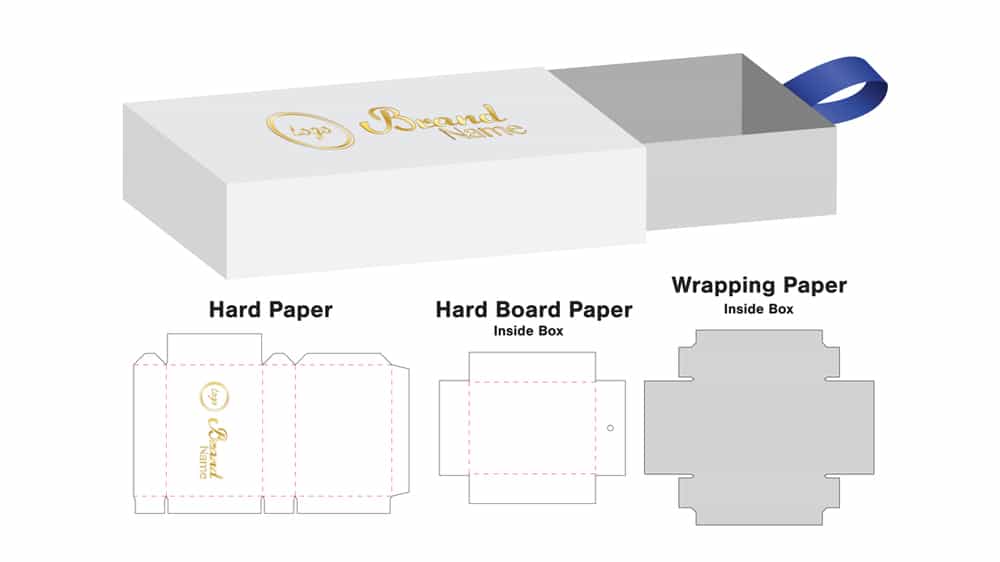

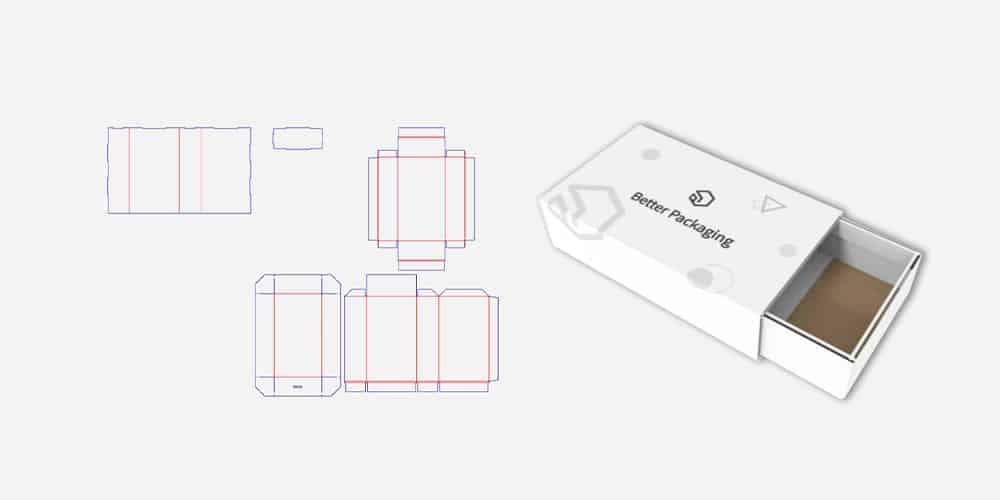

Drawer box

There are two parts, the inner box and sleeve, which are opened and closed by drawing. It is a better packaging method with the same texture as the lid and tray Box, similarly, used more material and labor and the price is slightly higher. Gray board+paper is a widely used material. The drawer box has the sense of an opening ceremony, and the overall packaging quality is high, which is suitable for most types of products.

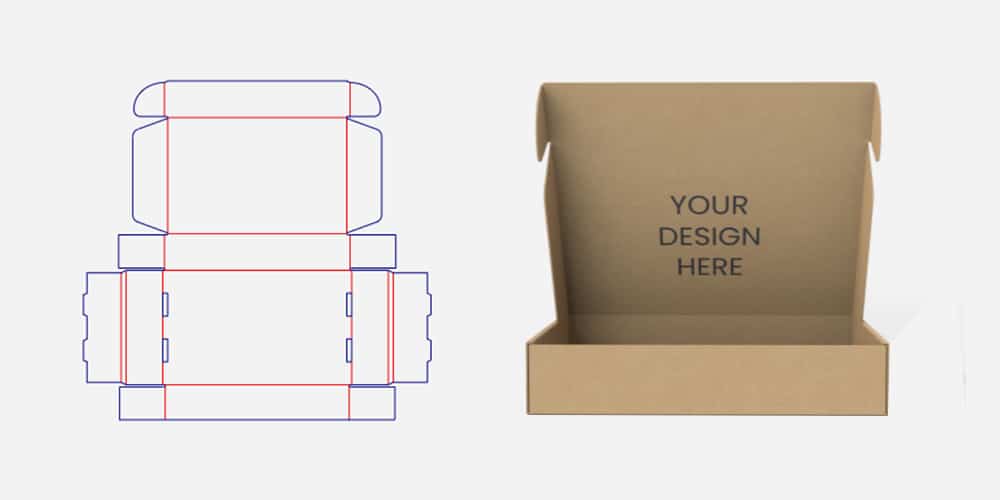

Aircraft box

As it is made of double-wall corrugated, it is very strong and durable. It has one opening on the top, with two closed flaps folded to the bottom of the box with friction locks. When unfolded, it is a whole piece of chopped paper, it does not need to be pasted, which can save processing costs and is often used for express packaging. Great for displaying multiple items in one box.

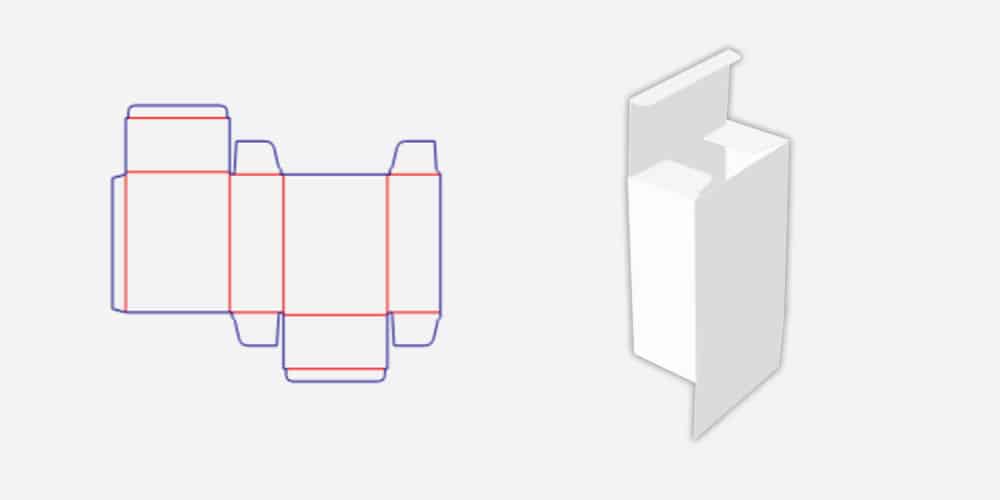

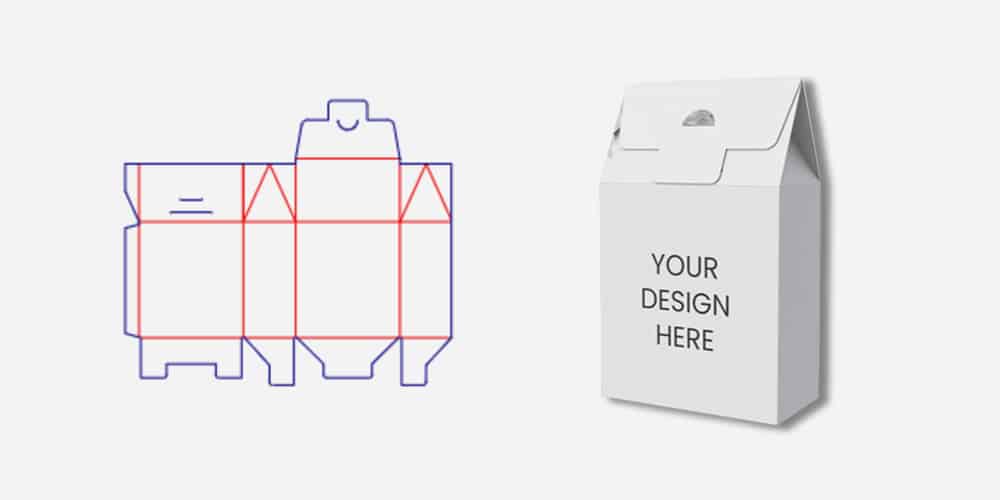

Hang tab box

The bottom is an inserted structure to increase the load capacity, the upper is designed with a hang hole to facilitate hanging on the shelf, which is also its biggest feature. You can place it at the point of sale, such as the cash register. In the cosmetics industry, hanging tab boxes are generally in the form of roof style, which can be made of white cards or kraft paper.

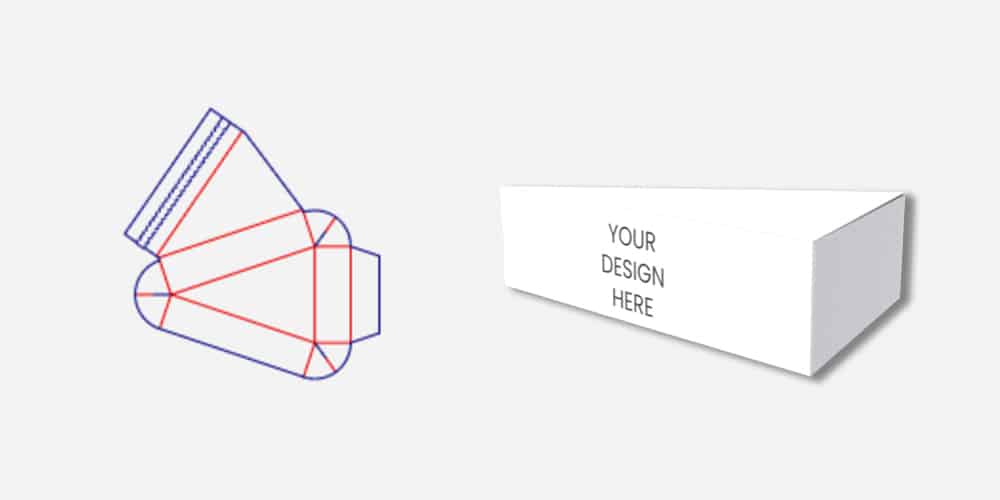

Polygon box

It can be in the form of a lid-and-tray, an ordinary folding box, or a window box. However, the shape is a pentagon or hexagon and other polygons. The boutique gift box gives a sense of stability and atmosphere, and the special shape makes a deep impression on consumers.

Book-type box

The packaging style is like a book; the box is opened from one side, composed of a panel and a bottom box. Most are made of hardboard, with other materials such as magnets, iron sheets, and others. It is one of the box-type options for high-end gifts.

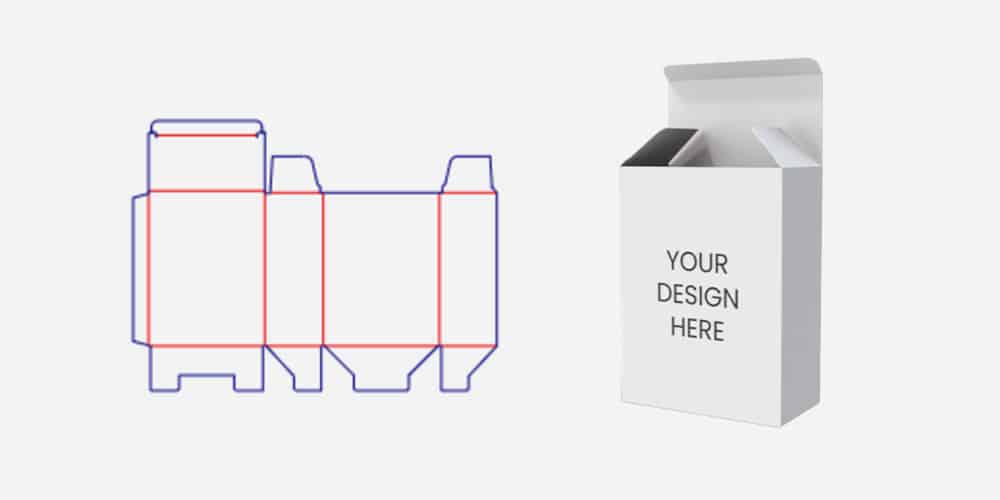

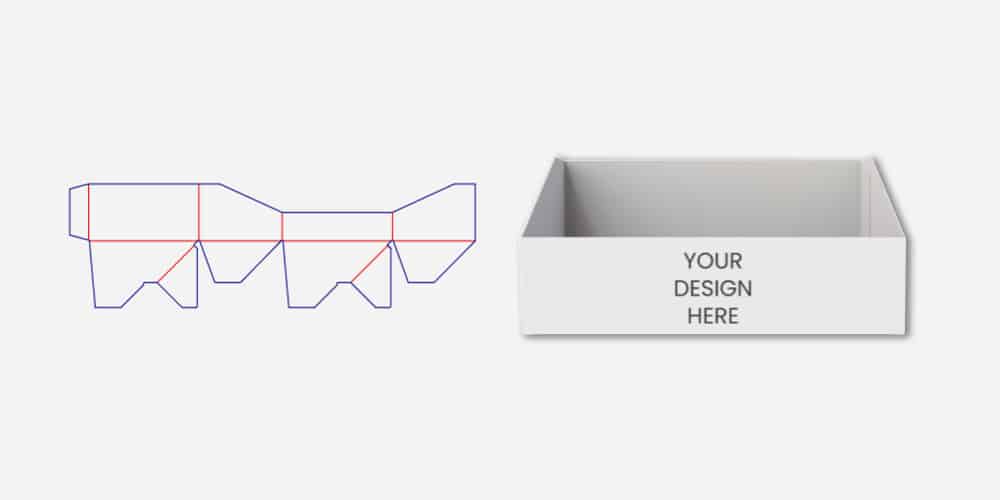

Display Box(PDQ)

Also named PDQ(Products Display Quickly). It’s “two boxes in one”, there are two purposes, packaging and displaying contents. When the lid is opened, it becomes a display. When it is closed, it protects and carries the contents. It has a greater visual impact when displayed on the shelf, ideal for selling smaller items as “gram and go”. Most are made of corrugated paper.