In addition to protecting the contents and showing the selling point, the packaging materials themselves also have potential safety issues. Some may contain toxic substances and toxic molecules may infiltrate into the content, which will greatly change the content’s quality and even cause great harm to the human body. This harm is no less than that of non-safety products to the body.

There are two main factors affecting safety in packaging materials, one is additives, and the other is heavy metals.

Additives: The most widely and frequently used now is plastics. Compared with ceramics, glass and other materials, it has outstanding advantages – lightweight, high strength, good resistance and low cost. However, its defect is also obvious – it is difficult to be degraded. Generally, the time to be decomposed by nature is 500 years. There are many classifications of additives, the most common of which are:

- Filler: used to change the hardness, abrasion resistance and dimensional stability of plastics, mainly including gypsum, metal powder, paper and wood.

- Plasticizer: It is used to strengthen the flexibility, elasticity and fluidity of plastics, such as phthalic acid and epoxy compounds.

- Stabilizer: It can prevent aging and degradation. Aromatic amine is commonly used.

- Colorants: change the color of materials to make them more attractive.

Many of them are toxic and harmful substances, such as phthalates and amine compounds. These additives themselves may be toxic and easily infiltrate into the contents, laying a hidden danger to human health.

Therefore, most countries and areas have formulated perfect laws and regulations, which clearly specify the types of plastics, adhesives, and inks used in food or drug packaging and adopt the “clear list system”. Here are the lists from the EU, USA, and China:

- Commission Directive 2002/72/EC

- Inventory of Effective Food Contact Substance

- GB 9685-2016 Safety Requirements for Food Contact Materials and Products

Heavy metals: excessive intake of heavy metals by the human body will cause great damage to health. For example, excessive lead will interfere with the synthesis of heme, affecting intellectual development and the reproductive system; Long term skin contact with excessive chromium compounds is likely to cause contact dermatitis and eczema; Mercury can affect the central nervous system.

Not only ceramics and glasses, but also metals, coatings, and even paper products contain more or less a certain amount of heavy metals – such as tin cans, paper with coatings or adhesives added, etc. Such packaging materials will slowly penetrate into the contents when in contact with weak acidic, and consumers will virtually absorb these toxic substances when using them.

In the current standard, both the USA TPCH and EU 94/62/EC Directives clearly point out that the total content of heavy metals (Pb, Cd, Hg, Cr+6) in packaging can’t exceed 100 ppm.

While paying attention to the safety and health of packaging materials, people also attach importance to their environmental protection issues.

According to Earthday, an estimated 583 billion plastic bottles were produced in 2021, and five trillion plastic bags will be used. This is terrible data, which also reminds us that industrialization brings high-quality life, but also affects the environment around us. If we don’t pay attention, we will turn our homes into garbage dumps.

In recent years, various countries attach great importance to environmental protection, which affects the packaging of industrial products, while the cosmetics industry attaches great importance to packaging. Undoubtedly, environmental protection has become an important factor in packaging.

Cosmetic packaging contains a large number of plastic and glass that are not easy to degrade and are corrosion resistant, which also causes environmental problems. Therefore, ECO packaging materials are the mainstream, and sustainable packaging is also proposed. At present, most companies consider the ECO innovation of packaging from both materials and structures. Replace plastic and metal packaging with biodegradable recycled paper and natural resin packaging, and pay more attention to the sustainability of the material.

Sustainable packaging follows the “4RID” principle, that is:

- Reduce: Reducing the packaging, appropriately and moderately designed, can not only save resources but also reduce the cost of the product.

- Reuse: These packaged products are designed to be a durable system that ensures effective recycling and returns for continuous use.

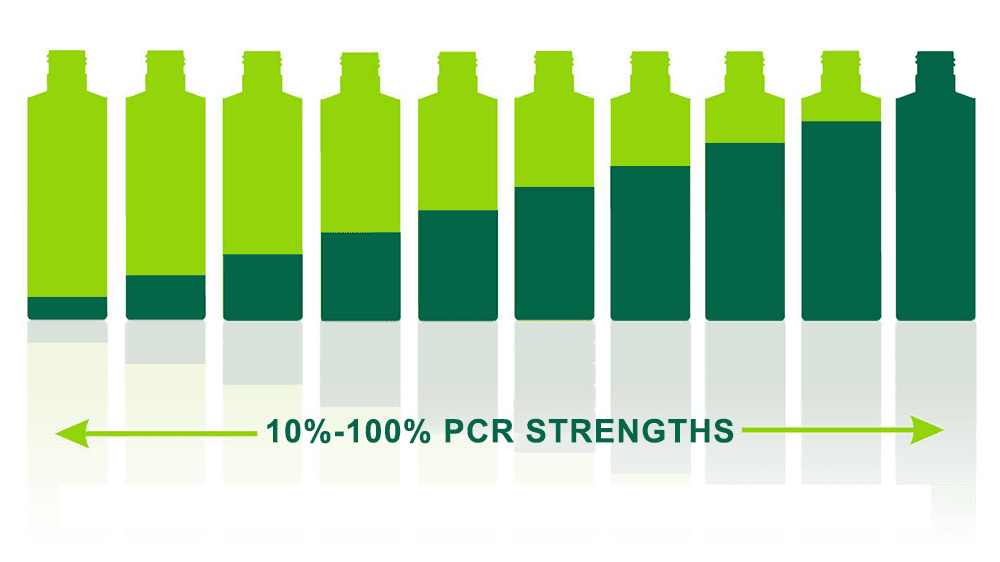

- Recycle: Recycling is a process of collecting and processing materials, that is, the materials themselves can be re-manufactured into the same but new products, such as paper, and PET.

- Refill: When the contents of the original plastic bottle you bought are used up, you can buy the contents again (in the bag) and fill them in, the bottle is a refilled bottle. The bag use less plastic than the bottle.

- Degradable: Anything that can be broken down either biologically or chemically.

However, as cosmetics are chemical products, the chemical stability of containers is required to be high, and most sustainable packaging uses natural materials that can be completely decomposed, which is difficult to achieve the physical and chemical properties of traditional containers. Therefore, there is a contradiction between the two factors, which causes enterprises to have new ideas in packaging. read more

In summary, the choice of packaging for cosmetics is no longer just about cost, but more about customer safety and environmental protection. The original “cost only” and “market only” business ideas must be abandoned. Sustainable development will certainly become the mainstream of packaging, which is not only the requirement of the times but also the social responsibility of each company.