Plastic containers are a great choice for cosmetics for many reasons; they are lightweight, durable and drop-proof, easy to transport, easy to produce, and you can make them into any shape and size you want. However, plastic is indeed no very ECO, but based on the current realities of the industry, we can’t abandon it completely. Here we will share some information about some commonly used plastics to make your choice easier.

PET

Polyethylene glycol terephthalate, is an environmentally friendly material, with high airtightness, good pressure strength, and high water resistance, the transparency is up to 95% which is higher than other materials, without capillaries can be used as alcohol packing containers.

Non-toxic, odorless, good hygiene and safety, can be used directly for food packaging. In cosmetics, 90% of plastic containers are now made of PET.

Cons: poor corona resistance, no resistance to heat and water immersion, and no resistance to alkali.

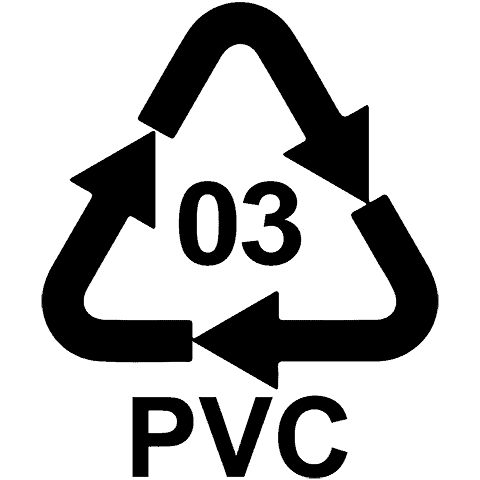

PVC

Polyvinyl chloride, high-temperature resistance, friction resistance, strong acid resistance, and stable internal structure, but poor stability to light and heat and must be added as a stabilizer in practical application.

PVC was once the world’s most produced general plastic and was used in a wide range of applications. However, on October 27, 2017, PVC is listed in the IARC Group 3 carcinogens.

In cosmetics, people are also gradually abandoning this unhealthy material, it is mostly used for the tray in paper box. and the largest use is currently the production of water pipes for building materials and the enameled outer wire of electric cables.

PP

Polypropylene, is a thermoplastic synthetic resin with excellent performance, colorless and translucent, chemical resistance, heat resistance, electrical insulation, high strength mechanical properties, high abrasion resistance, and processing properties, and is one of the lightest of all plastics. It is particularly stable to water, the water absorption rate is only 0. 01%. and it is BPA-free.

Cons: low dimensional accuracy, insufficient rigidity, poor weather resistance, post-shrinkage phenomenon, easy to aging, brittle, easy to deformation.

In cosmetic applications, PP is mostly used to make jars or pumps.

HDPE

High-Density Polyethylene, white powder or granular, good abrasion resistance, electrical insulation, toughness and cold resistance; good chemical stability, at room temperature, insoluble in any organic solvents, resistant to acid, alkali and various salts. It is commonly used in cosmetic bottles.

Cons: poor mechanical properties, poor air permeability, easy to deformation, easy to aging, easy to brittle, difficult to print.

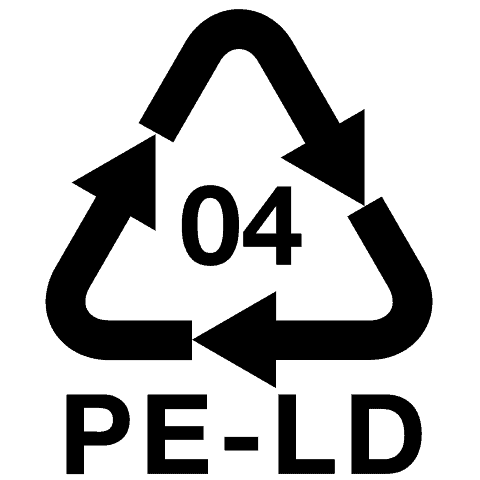

LDPE

Low-Density Polyethylene, the lightest variety of polyethylene resin, is milky white, tasteless, odorless, non-toxic, wax-like particles without luster. It has good softness, extensibility, electrical insulation, transparency, easy processing, and certain permeability. Its chemical stability performance is good, alkali resistance, and resistance to general organic solvents. Mainly used to make cosmetic tubes.

Cons: poor in mechanical strength, moisture barrier, gas barrier, and solvent resistance.

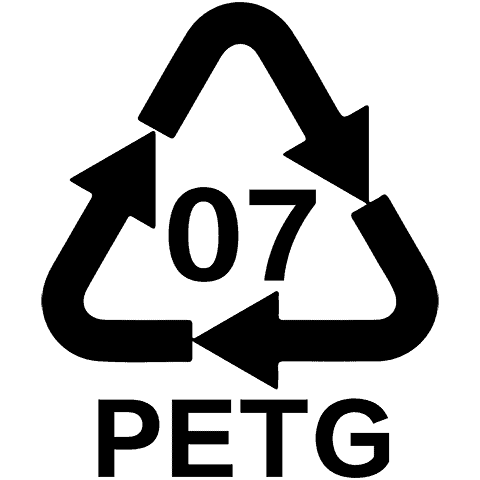

PETG

It can simply be an upgraded version of PET, commonly used in high-end cosmetic packaging. With outstanding toughness and high impact strength, wide processing range, high mechanical strength, and excellent flexibility, perfect gloss, chemical resistance, and easy processing, ability to injection molding, high transparency.

It is also capable of producing unique shapes, appearances, and special effects, such as bright colors, frosting, marble texture, metallic luster, etc. It is often used in high-grade cosmetics. After burning, only CO2 and water are left, making it the primary choice for environmentally friendly materials today.

Cons: not heat resistant, heat deflection temperature is only 75℃, difficult to dry during production, and the price is high.

PLA

Polylactic Acid, a new type of biodegradable material, is made from starch raw material proposed by renewable plant resources (such as corn). After use, it can be completely degraded by microorganisms in nature, eventually generating carbon dioxide and water, without polluting the environment, in addition to biocompatibility, gloss, transparency, hand feels and heat resistance.

Cons: not heat resistant, not UV resistant, expensive, unstable raw materials, still under development.

Summary

- Most of the plastic bottles are not 100% composed of a single material, for example, PP material itself is translucent, in order to improve its molding transparency, Benzoic acid can be added.

- Although the various types of plastics differ, each type of plastic may leach harmful substances if placed in extreme environments, such as extreme heat.

- Although experts are currently working on inventing the best methods and strategies to recycle all of these types of plastics, but only PET and HDPE are the most workable materials.

- The three plastics considered to be safe choices are PET, PP, HDPE.

| Material | Density | Tensile strength | Hardness | Water absorption | Visible | Application | Recycling Code |

| PET | 1.33g/cm³ | 49.2MPa | D81 | 0.297% | 95% | Bottle, Tray |  |

| PP | 0.93g/cm³ | 29.2MPa | D68 | 0.071% | 83% | Jar, Lid, pump |  |

| HDPE | 0.95g/cm³ | 22.1MPa | D64 | 0.015% | 0% | Bottle |  |

| LDPE | 0.92g/cm³ | 10.9MPa | D48 | 0.01% | 76% | Tube |  |

| PVC | 1.29g/cm³ | 43.2MPa | D68 | 0.26% | 86% | Tray |  |

| PETG | 1.26 g/cc | 47.6 MPa | D106 | 0.146 % | 90% | High-end bottle |  |

| PLA | 1.28g/cm³ | 62.9MPa | D71 | 0.244% | 90% | Bottle | Degradable |