Among the existing packaging materials, the PET bottle is the most popular, its durability is better than others. However, this kind of plastic has caused pressure on the treatment of environmental pollution and aroused the concern of consumers. Therefore, PCR has attracted more attention.

Post-consumer resin (PCR) is the technical term for plastic that has already been recycled and is ready to use again. It is composed of a mixture of recycled materials, otherwise, these materials will become municipal waste and can only be treated by incineration or landfill.

What are the benefits of PCR

- First of all, it helps protect the environment. virgin plastics are made from fossil fuels. When PCR is reused, there is no need for new fossil fuels, which will protect the environment much better. Moreover, the more used PCR, the greater the demand, which in turn promotes the recycling of plastic packaging.

- According to data from the Environmental Protection Agency, recycled plastic has much less impact on the environment than its original plastic. Many studies have shown that recycled plastics have more than 25% less greenhouse gas/carbon emissions than virgin resins.

- Consumption trend: the world’s leading brands have announced their commitment to use more PCR packaging. This view of sustainable development is being recognized by more and more industries, companies and consumers. Using PCR allows you to introduce sustainability and environmental responsibility into your business model and gain more consumer recognition.

- Meet the quality requirements of conventional packaging: PCR can provide the same level of protection, barrier performance and strength as ordinary plastics. You don’t have to worry about the penetration of light, oxygen and other gases into your products.

What are the drawbacks of PCR

- not suitable for all industries: PCR is not suitable for the application in pharmaceutical or medical industries due to the risk of pollution or lack of consistency.

- Flaws: The most common complaint of PCR resins is the occasional black spots, gray/yellow staining, and gels in the material. These minor defects will not affect the overall function of the product, strictly speaking, they are only decorative.

- cost: As the materials that really conform to PCR also need a series of product screening, sorting and purification processes, otherwise it may lead to a series of risks such as exceeding the standard of harmful substances; Not all recycled products can be put into reproduction, so the cost is higher than that of direct polymerization products.

How to make PCR

It can be roughly understood that PCR means plastic raw materials are converted into consumer goods through production, and after completing their own life cycle, they are sorted and recycled; afterward, the recycled materials have to undergo pretreatment (sorting, cleaning, defoaming, etc.) → crushing →washing and stirring→mixing and homogenization→plasticizing→granulation or re-product molding.

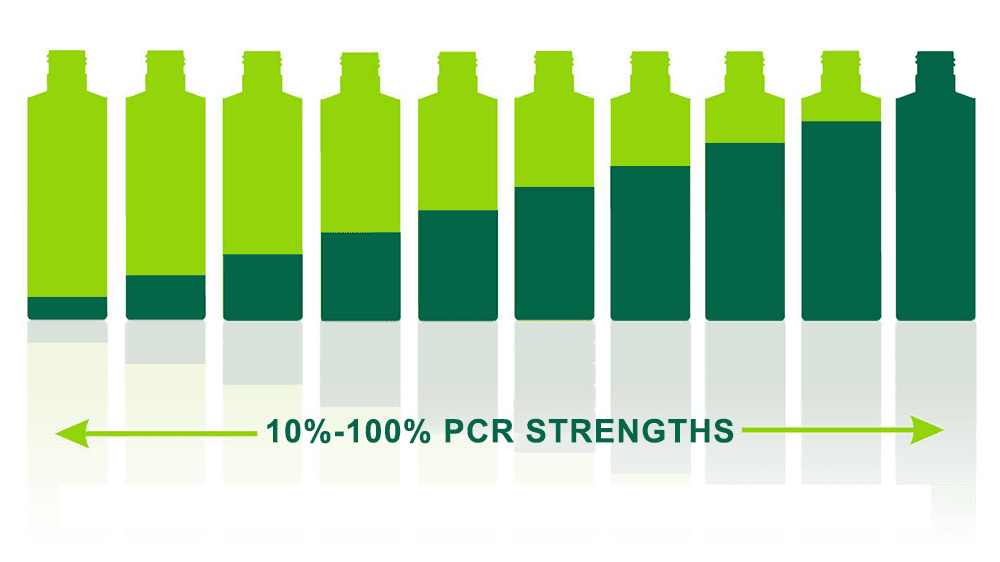

When manufacturing, the factory can produce different proportions of PCR according to demand, from 10% up to 100%. The higher the proportion of PCR, the greater the contribution to environmental protection. Here is the production process:

- Consumer purchase and use plastic products

- Consumers dispose of plastic products in accordance with the correct waste recycling program

- The local council collects the recyclable waste

- The recycling center sorts garbage according to the correct category

- Special equipment for cleaning and grinding plastic

- Melt and made into pellets

- PCR is produced into a new product

Is there any other ECO-friendly packaging

Yes, there are other products on the market that can provide substantial benefits to the environment, including:

- PIR: PIR(Post Industrial Recycled) refers to the wastes and leftovers directly recovered from the industrial production process. The most common ones here are the flow channels and substandard wastes of injection molding plants. This part of raw materials has not been processed into products and circulated in the market. It is still environmentally friendly and is significantly due to PCR in terms of consistency.

- Bio-based material:It is a material intentionally made from substances derived from living (or once-living) organisms. which are usually degradable, but this is not always the case.

- Biodegradable:It is a plastic that can be broken down by living organisms (microorganisms) into water, carbon dioxide and biomass. In principle, biodegradation can replace traditional plastic applications, but it also brings some challenges, such as the need for a well managed waste recovery system.

What certification need

If you want to prove your product is PCR, then you have to get the GRS(Global Recycled Standard) certification.